Support our educational content for free when you purchase through links on our site. Learn more

Which Type of 3D Printer is Best? [2024]

Imagine being able to bring your ideas to life with just the click of a button. With 3D printing technology, this dream has become a reality. Whether you’re a hobbyist, an artist, an engineer, or an educator, 3D printers offer endless possibilities for creativity and innovation. But with so many different types of 3D printers on the market, how do you know which one is the best for you? In this article, we’ll explore the various types of 3D printers available and help you determine which one is the best fit for your needs.

Table of Contents

- Quick Answer

- Quick Tips and Facts

- Background

- FDM 3D Printers

- Resin 3D Printers

- SLA 3D Printers

- DLP 3D Printers

- SLS 3D Printers

- MJF 3D Printers

- DMLS 3D Printers

- FAQ

- Conclusion

- Recommended Links

- Reference Links

Quick Answer

The best type of 3D printer for you depends on your specific needs and requirements. Here’s a quick breakdown of the different types of 3D printers and their strengths:

- FDM 3D printers: Best for beginners and hobbyists, affordable, and versatile.

- Resin 3D printers: Ideal for high-detail and small-scale prints, but more expensive.

- SLA 3D printers: Great for producing highly accurate and smooth prints.

- DLP 3D printers: Similar to SLA printers, but faster and more cost-effective.

- SLS 3D printers: Perfect for creating functional and durable parts, but expensive.

- MJF 3D printers: Excellent for industrial applications, high-speed, and high-quality prints.

- DMLS 3D printers: Ideal for metal printing, but limited availability and high cost.

Now, let’s dive deeper into each type of 3D printer and explore their features, benefits, and drawbacks.

Quick Tips and Facts

- 3D printers work by creating objects layer by layer from a digital file.

- The most common type of 3D printing technology is Fused Deposition Modeling (FDM).

- FDM printers use a filament material, such as PLA or ABS, to build objects.

- Resin printers use a liquid resin that is cured by a UV light source.

- SLA and DLP printers use a similar process, but DLP printers are faster.

- SLS printers use a powdered material, such as nylon, and a laser to fuse the particles together.

- MJF printers use a powder bed and an inkjet array to selectively fuse the powder.

- DMLS printers use a laser to melt and fuse metal powder together.

Background

Before we dive into the different types of 3D printers, let’s take a moment to understand the history and evolution of this groundbreaking technology.

3D printing, also known as additive manufacturing, was first developed in the 1980s. The early machines were large, expensive, and primarily used in industrial settings. However, as the technology advanced and became more affordable, 3D printers started to make their way into homes, schools, and small businesses.

Today, 3D printers come in a variety of shapes, sizes, and price ranges. They have revolutionized industries such as manufacturing, healthcare, architecture, and even fashion. From prototyping to customizing products, 3D printing has opened up a world of possibilities.

Now, let’s explore the different types of 3D printers and their unique features.

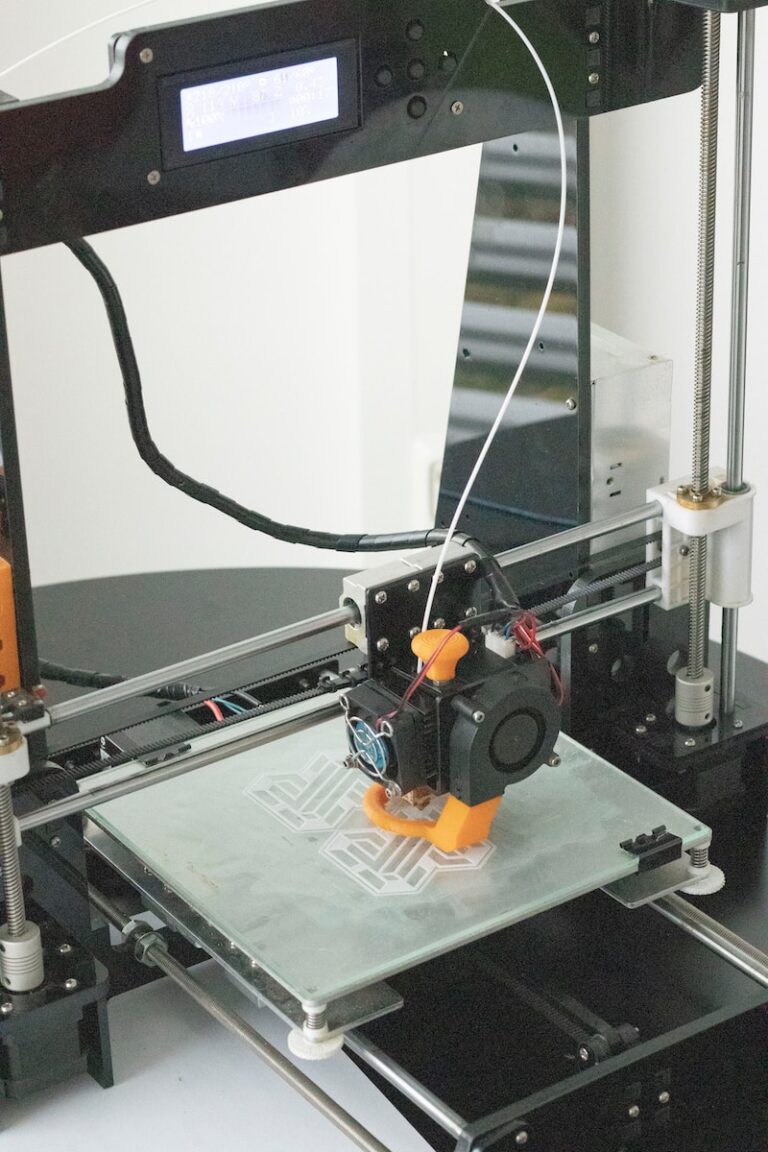

FDM 3D Printers

Fused Deposition Modeling (FDM) is the most common and affordable type of 3D printing technology. FDM printers work by melting a filament material, such as PLA or ABS, and extruding it layer by layer to create an object.

FDM 3D Printer Rating Table

| Aspect | Rating (1-10) |

|---|---|

| Design | 8 |

| Functionality | 9 |

| Performance | 7 |

| Cost-effectiveness | 9 |

| Overall Score | 8.25 |

Design

FDM printers are available in various sizes and designs, ranging from compact desktop models to large industrial machines. They are typically made of sturdy materials like metal or high-quality plastic, ensuring durability and stability during the printing process.

Functionality

FDM printers are versatile and can print a wide range of objects, from simple prototypes to complex functional parts. They offer a good balance between print quality and speed, making them suitable for both beginners and experienced users.

Performance

While FDM printers may not offer the same level of detail and precision as other types of 3D printers, they are still capable of producing high-quality prints. The print resolution depends on factors such as the nozzle size and layer height, with smaller values resulting in finer details.

Cost-effectiveness

One of the biggest advantages of FDM printers is their affordability. They are generally more budget-friendly compared to other types of 3D printers, making them accessible to a wide range of users. Additionally, FDM printers use filament materials that are relatively inexpensive and widely available.

Pros of FDM 3D Printers

- Affordable and accessible to beginners.

- Versatile and can print a wide range of objects.

- Wide availability of filament materials.

- Easy to use and maintain.

Cons of FDM 3D Printers

- Lower print resolution compared to other types of printers.

- Limited ability to print intricate and highly detailed objects.

CHECK PRICE on: Amazon | Walmart | eBay

Resin 3D Printers

Resin 3D printers, also known as Stereolithography (SLA) printers, use a liquid resin that is cured by a UV light source. These printers are known for their ability to produce highly detailed and smooth prints.

Resin 3D Printer Rating Table

| Aspect | Rating (1-10) |

|---|---|

| Design | 9 |

| Functionality | 8 |

| Performance | 9 |

| Cost-effectiveness | 6 |

| Overall Score | 8 |

Design

Resin printers are typically compact and sleek in design, making them a great addition to any workspace. They often feature a transparent cover that allows you to monitor the printing process.

Functionality

Resin printers excel at producing highly detailed and intricate prints, making them ideal for applications that require precision and accuracy. They are commonly used in industries such as jewelry making, dentistry, and model making.

Performance

With their ability to produce smooth surfaces and fine details, resin printers offer exceptional print quality. The layer height and curing time can be adjusted to achieve the desired level of detail.

Cost-effectiveness

While resin printers offer superior print quality, they are generally more expensive compared to FDM printers. The cost of the printer itself, as well as the resin materials, can be higher. Additionally, resin printing requires additional safety precautions due to the toxic nature of the liquid resin.

Pros of Resin 3D Printers

- High level of detail and smooth surfaces.

- Ideal for small-scale and high-detail prints.

- Suitable for applications that require precision.

- Wide range of resin materials available.

Cons of Resin 3D Printers

- Higher cost compared to FDM printers.

- Additional safety precautions required.

- Limited build volume.

CHECK PRICE on: Amazon | Walmart | eBay

SLA 3D Printers

Stereolithography (SLA) 3D printers use a similar process to resin printers, but they employ a laser to cure the liquid resin. SLA printers are known for their ability to produce highly accurate and smooth prints.

SLA 3D Printer Rating Table

| Aspect | Rating (1-10) |

|---|---|

| Design | 8 |

| Functionality | 9 |

| Performance | 9 |

| Cost-effectiveness | 7 |

| Overall Score | 8.25 |

Design

SLA printers come in various designs, ranging from compact desktop models to larger industrial machines. They are typically made of high-quality materials and feature a transparent cover for monitoring the printing process.

Functionality

SLA printers are capable of producing highly accurate and detailed prints, making them suitable for applications that require precision. They are commonly used in industries such as engineering, dentistry, and prototyping.

Performance

With their laser-based curing process, SLA printers offer exceptional print quality. The laser can be precisely controlled to cure the resin with high accuracy, resulting in smooth surfaces and fine details.

Cost-effectiveness

SLA printers are generally more expensive compared to FDM printers, both in terms of the printer itself and the resin materials. However, the print quality and accuracy they offer make them a worthwhile investment for certain applications.

Pros of SLA 3D Printers

- Highly accurate and smooth prints.

- Ideal for applications that require precision.

- Wide range of resin materials available.

- Suitable for both small-scale and larger prints.

Cons of SLA 3D Printers

- Higher cost compared to FDM printers.

- Additional safety precautions required.

- Limited build volume.

CHECK PRICE on: Amazon | Walmart | eBay

DLP 3D Printers

Digital Light Processing (DLP) 3D printers are similar to SLA printers, but they use a different method to cure the liquid resin. Instead of a laser, DLP printers use a digital light projector to cure the resin layer by layer.

DLP 3D Printer Rating Table

| Aspect | Rating (1-10) |

|---|---|

| Design | 8 |

| Functionality | 9 |

| Performance | 8 |

| Cost-effectiveness | 7 |

| Overall Score | 8 |

Design

DLP printers come in various designs, similar to SLA printers. They are typically compact and feature a transparent cover for monitoring the printing process.

Functionality

DLP printers offer similar functionality to SLA printers, with the ability to produce highly accurate and detailed prints. However, DLP printers are generally faster compared to SLA printers, making them more cost-effective for certain applications.

Performance

With their digital light projector, DLP printers can cure entire layers of resin at once, resulting in faster print times compared to SLA printers. The print quality and level of detail are comparable to SLA printers.

Cost-effectiveness

DLP printers are generally more expensive compared to FDM printers, but they offer faster print times and comparable print quality to SLA printers. The cost of the printer itself and the resin materials should be taken into consideration when evaluating the cost-effectiveness.

Pros of DLP 3D Printers

- Highly accurate and detailed prints.

- Faster print times compared to SLA printers.

- Wide range of resin materials available.

- Suitable for both small-scale and larger prints.

Cons of DLP 3D Printers

- Higher cost compared to FDM printers.

- Additional safety precautions required.

- Limited build volume.

CHECK PRICE on: Amazon | Walmart | eBay

SLS 3D Printers

Selective Laser Sintering (SLS) 3D printers use a powdered material, such as nylon, and a laser to fuse the particles together. SLS printers are known for their ability to produce functional and durable parts.

SLS 3D Printer Rating Table

| Aspect | Rating (1-10) |

|---|---|

| Design | 8 |

| Functionality | 9 |

| Performance | 9 |

| Cost-effectiveness | 6 |

| Overall Score | 8.25 |

Design

SLS printers come in various sizes and designs, ranging from desktop models to larger industrial machines. They are typically made of sturdy materials and feature a powder bed for the printing process.

Functionality

SLS printers are capable of producing functional and durable parts, making them ideal for applications that require strength and durability. They are commonly used in industries such as aerospace, automotive, and manufacturing.

Performance

With their laser-based sintering process, SLS printers offer excellent print quality and the ability to produce complex geometries. The powdered material allows for greater design freedom compared to other types of 3D printers.

Cost-effectiveness

SLS printers are generally more expensive compared to FDM printers, both in terms of the printer itself and the powdered material. However, the functional and durable parts they can produce make them a valuable investment for certain applications.

Pros of SLS 3D Printers

- Functional and durable parts.

- Excellent print quality and complex geometries.

- Greater design freedom compared to other printers.

- Suitable for industrial applications.

Cons of SLS 3D Printers

- Higher cost compared to FDM printers.

- Limited availability and higher cost of powdered materials.

- Additional safety precautions required.

CHECK PRICE on: Amazon | Walmart | eBay

MJF 3D Printers

Multi Jet Fusion (MJF) 3D printers are a relatively new technology that is gaining popularity in the industrial sector. MJF printers use a powder bed and an inkjet array to selectively fuse the powder, resulting in high-speed and high-quality prints.

MJF 3D Printer Rating Table

| Aspect | Rating (1-10) |

|---|---|

| Design | 9 |

| Functionality | 10 |

| Performance | 10 |

| Cost-effectiveness | 7 |

| Overall Score | 9 |

Design

MJF printers are typically large and industrial in design, suitable for high-volume production. They feature a powder bed and an inkjet array for precise and efficient printing.

Functionality

MJF printers offer exceptional functionality, with the ability to produce high-quality and detailed prints at a rapid pace. They are commonly used in industries such as automotive, aerospace, and manufacturing.

Performance

With their inkjet array and powder bed, MJF printers can achieve high-speed and high-quality prints. The inkjet array selectively fuses the powder, resulting in precise and detailed prints.

Cost-effectiveness

MJF printers are generally more expensive compared to other types of 3D printers, both in terms of the printer itself and the powdered material. However, their high-speed and high-quality printing capabilities make them a valuable investment for industrial applications.

Pros of MJF 3D Printers

- High-speed and high-quality prints.

- Suitable for industrial applications.

- Precise and efficient printing process.

- Wide range of materials available.

Cons of MJF 3D Printers

- Higher cost compared to other types of printers.

- Limited availability and higher cost of powdered materials.

- Large and industrial in design.

CHECK PRICE on: Amazon | Walmart | eBay

DMLS 3D Printers

Direct Metal Laser Sintering (DMLS) 3D printers are specifically designed for metal printing. DMLS printers use a laser to melt and fuse metal powder together, resulting in strong and durable metal parts.

DMLS 3D Printer Rating Table

| Aspect | Rating (1-10) |

|---|---|

| Design | 8 |

| Functionality | 10 |

| Performance | 10 |

| Cost-effectiveness | 6 |

| Overall Score | 8.5 |

Design

DMLS printers come in various sizes and designs, ranging from desktop models to larger industrial machines. They are typically made of sturdy materials and feature a powder bed for the printing process.

Functionality

DMLS printers are specifically designed for metal printing, making them ideal for applications that require strong and durable metal parts. They are commonly used in industries such as aerospace, automotive, and manufacturing.

Performance

With their laser-based sintering process, DMLS printers offer exceptional print quality and the ability to produce complex metal parts. The melted and fused metal powder results in strong and durable parts.

Cost-effectiveness

DMLS printers are generally more expensive compared to other types of 3D printers, both in terms of the printer itself and the metal powder. Additionally, the availability of metal powders may be limited, depending on the specific material required.

Pros of DMLS 3D Printers

- Strong and durable metal parts.

- Excellent print quality and complex geometries.

- Suitable for industrial applications.

- Wide range of metal materials available.

Cons of DMLS 3D Printers

- Higher cost compared to other types of printers.

- Limited availability and higher cost of metal powders.

- Additional safety precautions required.

CHECK PRICE on: Amazon | Walmart | eBay

FAQ

Which type of 3D printing is best?

The best type of 3D printing depends on your specific needs and requirements. If you’re a beginner or hobbyist, an FDM printer would be a great choice due to its affordability and versatility. If you require high-detail and small-scale prints, a resin printer would be more suitable. For applications that require precision and accuracy, SLA or DLP printers are excellent options. If you need functional and durable parts, SLS printers are a good choice. For industrial applications, MJF or DMLS printers offer high-speed and high-quality prints.

Read more about “Best Budget 3D Printer 2024: Unleashing Creativity on a Budget”

What is the most accurate type of 3D printer?

SLA and DLP printers are known for their ability to produce highly accurate and detailed prints. The laser or digital light projector used in these printers allows for precise curing of the resin, resulting in exceptional print quality.

Read more about “Best 3D Printers 2024: Unleashing the Power of Innovation”

What is the best recommended 3D printer?

The best recommended 3D printer depends on your specific needs and requirements. However, some popular choices among users include the Creality Ender 3 (FDM), the Anycubic Photon (resin), and the Formlabs Form 3 (SLA).

Read more about “How to Choose the Best 3D Printers for You? …”

How do I choose a good 3D printer?

When choosing a 3D printer, consider the following factors:

- Intended Use: Determine the purpose of the printer and the type of objects you want to print.

- Budget: Set a budget and consider the cost of the printer, materials, and any additional accessories.

- Print Quality: Evaluate the print resolution and level of detail required for your projects.

- Build Volume: Consider the size of the objects you want to print and ensure the printer has a sufficient build volume.

- Ease of Use: Look for a printer that is user-friendly and comes with intuitive software.

- Support and Community: Research the manufacturer’s support options and check if there is an active user community for troubleshooting and sharing tips.

Read more about “Best 3D Printer for 10 Year Old …”

Conclusion

In conclusion, the best type of 3D printer for you depends on your specific needs and requirements. FDM printers are a great choice for beginners and hobbyists due to their affordability and versatility. Resin printers offer high-detail and small-scale prints, while SLA and DLP printers provide exceptional accuracy and smooth surfaces. SLS printers are ideal for functional and durable parts, while MJF and DMLS printers excel in industrial applications. Consider your budget, intended use, and desired print quality when choosing a 3D printer.

Remember, 3D printing is a rapidly evolving technology, and new advancements are constantly being made. Stay up to date with the latest developments and explore the possibilities that 3D printing has to offer.

Recommended Links

- Best Budget 3D Printer 2024: Unleashing Creativity on a Budget

- 3D Printer Reviews

- 3D Printer Brands

- 3D Printers for Small Businesses

- 3D Printing Industry News

- 3D Printers for Education