Support our educational content for free when you purchase through links on our site. Learn more

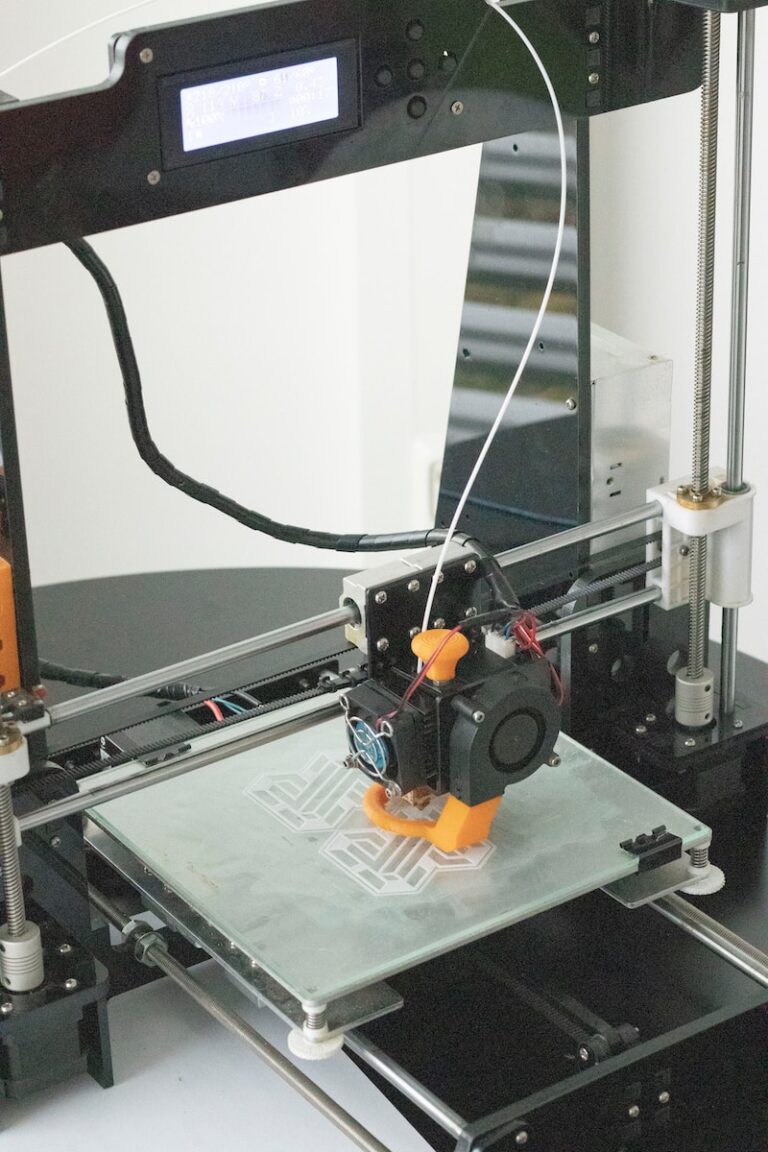

Industrial 3D Printer Price [2023]

Are you curious about the cost of industrial 3D printers? Look no further! At Best 3D Printer™, we’re here to provide you with all the information you need to make an informed decision. In this article, we’ll explore the price ranges of industrial 3D printers, discuss the factors to consider when investing in one, and provide expert advice to help you determine if it’s worth the price. So, let’s dive in!

Table of Contents

- Quick Answer

- Quick Tips and Facts

- Background

- How Much Does an Industrial 3D Printer Cost?

- Factors to Consider

- In-House 3D Printing vs. Outsourcing

- Business Impact

- FAQ

- Conclusion

- Recommended Links

- Reference Links

Quick Answer

The cost of an industrial 3D printer can vary significantly depending on various factors such as the printer’s capabilities, build volume, print speed, and material compatibility. On average, industrial 3D printers can range from $20,000 to over $1 million. However, it’s important to note that these prices are just a starting point, and the final cost can be influenced by additional factors such as maintenance, software, and materials.

✅ CHECK PRICE on: Amazon | Walmart | eBay

Quick Tips and Facts

- Industrial 3D printers are designed for high-volume production, rapid prototyping, and manufacturing applications.

- They offer larger build volumes, faster print speeds, and the ability to work with a wide range of materials.

- The cost of an industrial 3D printer is influenced by factors such as build volume, print speed, material compatibility, and additional features.

- In addition to the initial purchase cost, consider ongoing expenses such as maintenance, software, and materials.

- It’s important to assess your specific needs and requirements before investing in an industrial 3D printer.

Background

Before we dive into the details, let’s take a moment to understand the history and significance of industrial 3D printers. Industrial 3D printing, also known as additive manufacturing, has revolutionized the manufacturing industry by enabling the production of complex parts with high precision and efficiency. It has found applications in various industries, including aerospace, automotive, healthcare, and consumer goods.

How Much Does an Industrial 3D Printer Cost?

Now, let’s get to the heart of the matter—how much does an industrial 3D printer actually cost? The price of an industrial 3D printer can vary based on several factors, including:

- Build Volume: The size of the build volume, or the maximum size of the objects that can be printed, can significantly impact the price. Larger build volumes generally come at a higher cost.

- Print Speed: Faster print speeds can increase the price of an industrial 3D printer. High-speed printers are capable of producing parts more quickly, which can be advantageous for high-volume production.

- Material Compatibility: Industrial 3D printers can work with a wide range of materials, including plastics, metals, ceramics, and composites. The ability to print with different materials can affect the price.

- Additional Features: Some industrial 3D printers come with advanced features such as multi-material printing, dual extruders, and automated calibration. These additional features can contribute to a higher price tag.

To give you a better idea of the price ranges, here’s a breakdown:

| Price Range | Description |

|---|---|

| Entry Level | $20,000 – $50,000 |

| Mid-Range | $50,000 – $200,000 |

| High-End | $200,000 – $500,000 |

| Premium | $500,000 – $1,000,000 |

| Top-of-the-Line | $1,000,000+ |

It’s important to note that these price ranges are approximate and can vary depending on the specific model, brand, and additional features. Additionally, the prices mentioned above are for the printers themselves and do not include ongoing expenses such as maintenance, software, and materials.

Factors to Consider

When considering the purchase of an industrial 3D printer, it’s crucial to take into account several factors to ensure you make the right investment. Here are some key considerations:

- Application: Determine the specific applications and use cases for which you need an industrial 3D printer. Consider the required print volume, material compatibility, and print speed.

- Budget: Set a realistic budget for your industrial 3D printer investment. Remember to consider not only the initial purchase cost but also ongoing expenses such as maintenance, software, and materials.

- Support and Service: Research the reputation and track record of the manufacturer or supplier. Look for companies that offer reliable customer support, training, and maintenance services.

- Future Scalability: Consider your future needs and growth potential. Will the printer be able to meet your requirements as your business expands? Ensure that the printer you choose can scale with your needs.

- Compatibility: Ensure that the industrial 3D printer is compatible with the software and design tools you use. Compatibility issues can lead to inefficiencies and additional costs.

By carefully considering these factors, you can make an informed decision and choose an industrial 3D printer that aligns with your specific needs and budget.

In-House 3D Printing vs. Outsourcing

One important decision to make when considering industrial 3D printing is whether to invest in an in-house printer or outsource the printing to a 3D parts supplier. Let’s explore the pros and cons of each option:

In-House 3D Printing

Pros:

- Control: In-house 3D printing gives you full control over the entire printing process, from design to production. You can make changes and iterate quickly without relying on external suppliers.

- Confidentiality: If you’re working on sensitive or proprietary designs, in-house printing allows you to maintain confidentiality and protect your intellectual property.

- Cost Savings: Over time, in-house 3D printing can lead to cost savings compared to outsourcing, especially for high-volume production.

Cons:

- Initial Investment: Setting up an in-house 3D printing facility requires a significant upfront investment in equipment, software, and training.

- Maintenance and Upkeep: In-house printers require regular maintenance and upkeep, which can add to the overall cost and complexity.

- Expertise: Operating an industrial 3D printer requires expertise and specialized knowledge. You may need to invest in training or hire skilled personnel.

Outsourcing to a 3D Parts Supplier

Pros:

- Access to Expertise: By outsourcing to a 3D parts supplier, you gain access to their expertise and experience in 3D printing. They can provide guidance and support throughout the process.

- Flexibility: Outsourcing allows you to tap into a wide range of materials, technologies, and capabilities without the need for significant upfront investment.

- Scalability: If your production needs fluctuate, outsourcing provides the flexibility to scale up or down quickly without the need to invest in additional equipment.

Cons:

- Dependency: Outsourcing means relying on external suppliers, which can introduce delays and potential quality control issues.

- Confidentiality Concerns: If you’re working on sensitive designs, outsourcing may raise concerns about protecting your intellectual property.

- Cost: Depending on the volume and complexity of your parts, outsourcing can be more expensive in the long run compared to in-house printing.

Ultimately, the decision between in-house 3D printing and outsourcing depends on your specific needs, budget, and long-term goals. Consider the pros and cons carefully to make the right choice for your business.

Business Impact

Implementing industrial 3D printing can have a significant impact on your business. Here are some key areas where it can make a difference:

- Time-to-Market: 3D printing enables rapid prototyping and iteration, reducing the time it takes to bring a product to market. This can give you a competitive edge and allow for faster innovation.

- Cost Savings: By eliminating the need for traditional manufacturing processes and tooling, 3D printing can lead to cost savings, especially for low-volume production or complex geometries.

- Design Freedom: 3D printing allows for the creation of complex and intricate designs that would be challenging or impossible to produce using traditional methods. This opens up new possibilities for product design and functionality.

- Customization: With 3D printing, it’s easier to create customized products tailored to individual customer needs. This can enhance customer satisfaction and drive customer loyalty.

- Supply Chain Optimization: 3D printing can reduce reliance on traditional supply chains by enabling on-demand production and localized manufacturing. This can lead to shorter lead times and reduced inventory costs.

It’s important to evaluate the potential business impact of industrial 3D printing on your specific industry and applications. Consider the long-term benefits and weigh them against the initial investment and ongoing costs.

FAQ

How much does it cost to buy an industrial 3D printer?

The cost of an industrial 3D printer can range from $20,000 to over $1 million, depending on factors such as build volume, print speed, material compatibility, and additional features. It’s important to consider the specific requirements of your application and budget before making a purchase.

Read more about “… What Brand of 3D Printer is the Best?”

How much does an industrial printer cost?

Industrial 3D printers can range in price from $20,000 to over $1 million. The final cost depends on various factors such as build volume, print speed, material compatibility, and additional features.

Read more about “How Much is a 3D Printer for Home? …”

How much is a high-tech 3D printer?

High-tech 3D printers, which offer advanced features and capabilities, can range in price from $200,000 to $1 million or more. The cost depends on factors such as build volume, print speed, material compatibility, and additional features.

How much is an HP Jet Fusion 5200?

The HP Jet Fusion 5200 is a high-end industrial 3D printer that offers advanced capabilities for production-grade applications. The price of the HP Jet Fusion 5200 can vary depending on the specific configuration and additional features. For accurate pricing information, it’s best to contact an authorized HP reseller or visit the official HP website.

Conclusion

In conclusion, the cost of an industrial 3D printer can vary significantly depending on factors such as build volume, print speed, material compatibility, and additional features. While the initial investment may seem high, industrial 3D printing can offer numerous benefits such as faster time-to-market, cost savings, design freedom, and customization.

Before making a purchase, carefully consider your specific needs, budget, and long-term goals. Evaluate the pros and cons of in-house 3D printing versus outsourcing to determine the best approach for your business. If you decide to invest in an industrial 3D printer, ensure that you choose a reputable manufacturer or supplier and consider ongoing expenses such as maintenance, software, and materials.

At Best 3D Printer™, we recommend exploring our 3D Printer Reviews and 3D Printer Brands categories for more information on the best industrial 3D printers available in the market. Additionally, if you’re interested in 3D printing for small businesses or education, check out our 3D Printers for Small Businesses and 3D Printers for Education categories.

Remember, investing in an industrial 3D printer is a significant decision, and it’s important to do thorough research and consider all the factors before making a purchase.

Recommended Links

- CHECK PRICE on: Amazon | Walmart | eBay

- Shop HP Jet Fusion 5200 on: Amazon | Walmart | eBay | HP Official Website