Support our educational content for free when you purchase through links on our site. Learn more

[2023] How Much is a 3D Printer Cost? A Comprehensive Guide

Quick Answer:

The cost of a 3D printer can vary widely depending on the printing process, materials, and level of sophistication. Prices range from as low as $200 for entry-level DIY printer kits to over $500,000 for high-end industrial systems. The most common types of 3D printers, FDM (Fused Deposition Modeling) and SLA (Stereolithography), have starting prices of around $200 and $2,499, respectively. It’s important to consider not only the upfront cost of the printer but also ongoing expenses such as materials, maintenance, and upgrades.

Table of Contents:

- Quick Answer

- Quick Tips and Facts

- Background

- Types of 3D Printing Processes and Their Costs

- Factors Affecting 3D Printer Cost

- Calculating 3D Printing Costs

- Outsourced Production vs. In-House 3D Printing

- Considerations Beyond Direct Costs

- 3D Printing Cost Calculator

- FAQ

- Conclusion

- Recommended Links

- Reference Links

Quick Tips and Facts

- 3D printer prices can range from $200 to over $500,000, depending on the type and capabilities of the printer.

- Entry-level FDM printers typically start around $200 for DIY kits and $400 for pre-assembled models.

- SLA printers, which offer higher resolution and better quality, start at around $2,499 for professional desktop models.

- Industrial-grade SLS (Selective Laser Sintering) printers, suitable for medium to large volumes of high-quality parts, can start at $24,999.

- Metal 3D printers are the most expensive, with prices ranging from $100,000 to over $1 million.

- Additional costs to consider include materials, maintenance, upgrades, and software.

Shopping Links:

- CHECK PRICE on: FDM 3D Printers on Amazon

- CHECK PRICE on: SLA 3D Printers on Amazon

- CHECK PRICE on: SLS 3D Printers on Amazon

- CHECK PRICE on: Metal 3D Printers on Amazon

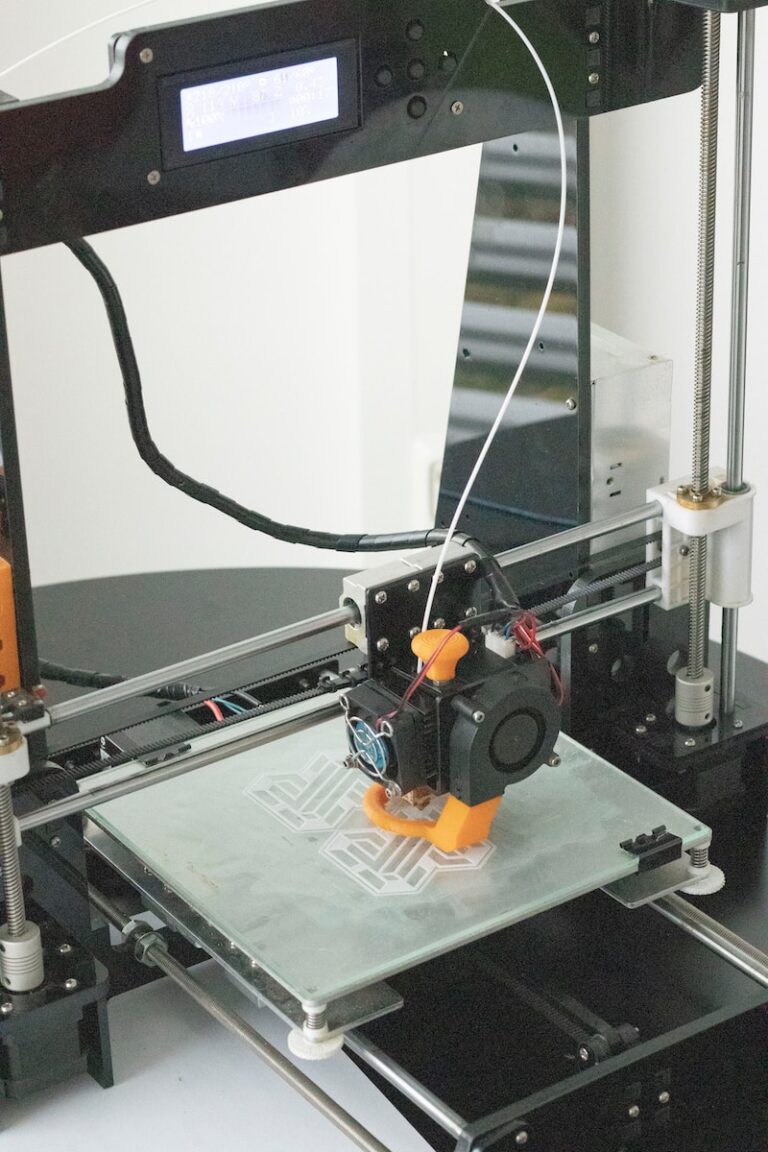

Background

3D printing, also known as additive manufacturing, has revolutionized the way we create objects. It allows for the production of complex and customized designs with ease. As the technology has advanced, the cost of 3D printers has become more accessible to individuals, small businesses, and large industries.

Types of 3D Printing Processes and Their Costs

There are several different types of 3D printing processes, each with its own advantages and cost considerations. The most common types include FDM, SLA, SLS, and metal 3D printing.

-

FDM (Fused Deposition Modeling): FDM printers are the most affordable and widely used type of 3D printer. They work by extruding melted filament layer by layer to create the desired object. Entry-level FDM printers can start as low as $200 for DIY kits and around $400 for pre-assembled models. Professional-grade FDM printers with larger build volumes and advanced features can range from $1,000 to $10,000.

-

SLA (Stereolithography): SLA printers use a liquid resin that is cured by a UV laser to create highly detailed and precise objects. SLA printers offer better resolution and surface finish compared to FDM printers. Professional desktop SLA printers start at around $2,499, while larger benchtop models can cost upwards of $8,999.

-

SLS (Selective Laser Sintering): SLS printers use a laser to selectively fuse powdered materials, such as nylon or metal, to create strong and functional parts. SLS is particularly suitable for producing medium to large volumes of high-quality parts. Benchtop industrial SLS systems can start at around $24,999.

-

Metal 3D Printing: Metal 3D printers are the most expensive due to the complexity of the technology and the high cost of metal powders. Prices for metal 3D printers can range from $100,000 to over $1 million, depending on the size, capabilities, and metal materials used.

Shopping Links:

- CHECK PRICE on: FDM 3D Printers on Amazon

- CHECK PRICE on: SLA 3D Printers on Amazon

- CHECK PRICE on: SLS 3D Printers on Amazon

- CHECK PRICE on: Metal 3D Printers on Amazon

Factors Affecting 3D Printer Cost

The cost of a 3D printer is influenced by various factors, including:

-

Printing Technology: Different printing technologies have different costs associated with them. FDM printers tend to be more affordable, while SLA and SLS printers are generally more expensive due to their higher precision and capabilities.

-

Build Volume: The size of the build volume, or the maximum size of the objects that can be printed, affects the cost of the printer. Larger build volumes generally come with a higher price tag.

-

Resolution and Print Quality: Higher resolution and better print quality often come at a higher cost. SLA printers, for example, offer superior resolution and surface finish compared to FDM printers, but they are typically more expensive.

-

Materials Compatibility: Some printers are designed to work with specific materials, while others offer more versatility. Printers that can handle a wider range of materials tend to be more expensive.

-

Ease of Use and Features: User-friendly interfaces, advanced features, and automation can increase the cost of a 3D printer. These additional features can be beneficial for users who value convenience and efficiency.

-

Brand and Reputation: Well-established brands with a reputation for quality and reliability often come with a higher price tag. However, they may also offer better customer support and a more refined user experience.

Calculating 3D Printing Costs

When considering the cost of a 3D printer, it’s important to take into account not only the upfront cost but also the ongoing expenses associated with 3D printing. These expenses can include:

-

Materials: The cost of materials can vary depending on the type of printer and the materials used. Filament for FDM printers is generally more affordable compared to resins or powders used in SLA, SLS, or metal printing.

-

Maintenance and Upgrades: Regular maintenance, such as replacing nozzles or cleaning print beds, can incur additional costs. Upgrades, such as adding heated beds or upgrading to higher-quality components, may also be necessary over time.

-

Energy Consumption: 3D printers require electricity to operate, and the energy consumption can vary depending on the printer’s size and features. It’s important to consider the ongoing energy costs associated with running a 3D printer.

-

Software and Design Tools: Some 3D printers come with proprietary software or design tools, while others may require the use of third-party software. The cost of software licenses or design tools should be factored into the overall cost.

Shopping Links:

- CHECK PRICE on: 3D Printer Filaments on Amazon

- CHECK PRICE on: 3D Printer Resins on Amazon

- CHECK PRICE on: 3D Printer Powders on Amazon

Outsourced Production vs. In-House 3D Printing

One important consideration when evaluating the cost of a 3D printer is whether to outsource production to a service bureau or invest in an in-house 3D printer. Here are some factors to consider:

Outsourced Production:

- ✅ Pros:

- Access to professional-grade equipment and expertise.

- No upfront investment in a 3D printer.

- Suitable for occasional or large parts that require specialized materials or processes.

- ❌ Cons:

- Longer lead times and potential shipping costs.

- Limited control over the production process.

- Higher costs for frequent or small-scale production.

In-House 3D Printing:

- ✅ Pros:

- Faster turnaround times for prototyping and small-scale production.

- Greater control over the production process and design iterations.

- Cost-effective for frequent or small-scale production.

- ❌ Cons:

- Upfront investment in a 3D printer and ongoing expenses.

- Requires knowledge and expertise in 3D printing.

- Limited to the capabilities of the chosen printer.

Considerations Beyond Direct Costs

When evaluating the cost of a 3D printer, it’s important to consider factors beyond direct costs. These considerations can have a significant impact on the overall value and benefits of 3D printing:

-

Time Savings: 3D printing can significantly reduce the time required for prototyping and production compared to traditional manufacturing methods. This can result in faster product development cycles and time-to-market.

-

Better Results: 3D printing allows for the creation of complex geometries and customized designs that may not be possible with traditional manufacturing methods. This can lead to improved product performance and functionality.

-

Improved Communication: 3D printing enables the creation of physical prototypes that can be used for design reviews, client presentations, and marketing purposes. This can enhance communication and collaboration throughout the product development process.

-

Intellectual Property (IP) Protection: In-house 3D printing can help protect sensitive designs and intellectual property by reducing the need to share files with external service providers.

3D Printing Cost Calculator

To help estimate the cost of 3D printing, you can use the interactive 3D printing cost calculator provided by Formlabs. This tool allows you to input various parameters, such as printer type, material usage, and labor costs, to calculate the cost per part and compare it to other production methods.

Formlabs 3D Printing Cost Calculator

FAQ

How much does a decent 3D printer cost?

The cost of a decent 3D printer can vary depending on the type and capabilities of the printer. Entry-level FDM printers can start as low as $200 for DIY kits and around $400 for pre-assembled models. Professional-grade FDM printers with larger build volumes and advanced features can range from $1,000 to $10,000. SLA printers, which offer higher resolution and better quality, start at around $2,499 for professional desktop models.

Read more about “… How Much is a Really Good 3D Printer? – The Ultimate Guide”

How much does a DIY 3D printer cost?

DIY 3D printer kits are a more affordable option for those who are willing to assemble and calibrate the printer themselves. DIY kits can start as low as $200, depending on the printer’s capabilities and features. While DIY printers require more effort to set up, they can be a cost-effective way to get started with 3D printing.

Read more about “… How Many Americans Own a 3D Printer? A Comprehensive Guide”

How much does it cost to 3D print for 1 hour?

The cost of 3D printing for 1 hour depends on various factors, including the type of printer, material usage, and electricity costs. As a rough estimate, the cost of filament for an FDM printer can range from $0.05 to $0.20 per gram. Therefore, the cost of 3D printing for 1 hour can range from a few cents to a few dollars, depending on the complexity and size of the printed object.

Read more about “… Is it Expensive to 3D Print? A Comprehensive Guide”

How much does a SLA 3D printer cost?

SLA printers, which offer higher resolution and better quality compared to FDM printers, typically start at around $2,499 for professional desktop models. Larger benchtop SLA printers with advanced features can cost upwards of $8,999. The cost of SLA printers can vary depending on the build volume, resolution, and additional features.

Read more about “… How Much is a 3D Printer for Home? Your Ultimate Guide”

Conclusion

In conclusion, the cost of a 3D printer can vary widely depending on the printing process, materials, and level of sophistication. Prices range from as low as $200 for entry-level DIY printer kits to over $500,000 for high-end industrial systems. When considering the cost of a 3D printer, it’s important to factor in ongoing expenses such as materials, maintenance, and upgrades. Additionally, it’s crucial to consider factors beyond direct costs, such as time savings, better results, improved communication, and IP protection. Overall, the choice of a 3D printer should be based on your specific needs, budget, and long-term goals.

Recommended Links

- 3D Printer Reviews

- 3D Printer Brands

- 3D Printers for Small Businesses

- 3D Printers for Education

- 2023 How Many Americans Own a 3D Printer? A Comprehensive Guide